road Patna, Bihar, India 800001

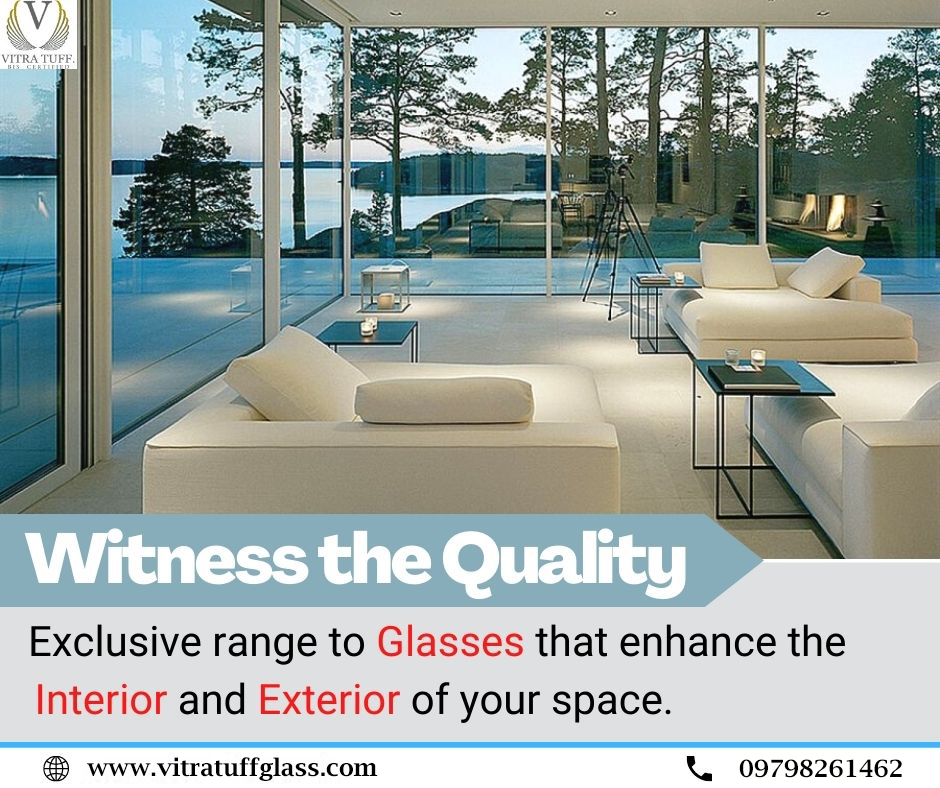

Overall Strengthening your Space with VitraTuff the best toughened glass company in Patna

Glass is recognized as a paradoxical material, displaying opposing attributes simultaneously; it is transparent and reflective, strong and fragile, material and immaterial. Developments in recent decades, however, have rendered the base material virtually unrecognizable and the remarkable diversity of material variations commonly referred to as glass. It also became a ubiquitous material in commercial building construction during the second half of the twentieth century, despite certain properties that tended to compromise the thermal performance of the building envelope. Vitra Tuff glasses, one of the primary toughened glass manufacturers in Patna recognize the value of quality glass manufacturing when it comes to furnishing your personal or commercial space.

Float Glass Manufacturing

Glass comes in a variety of forms as a function of chemistry and process. The basic ingredient, however, is silica, or sand, one of the most common and inexpensive materials on the planet. The addition of soda and lime, also very common materials, yields the most basic form of glass, generally referred to as soda-lime glass and the material used in the modern float process by which architectural glass is produced.

Conceptually, float glass manufacturing is a simple linear process. The raw materials are first mixed, heated to a melt temperature of approximately 1600°C (2732°F) and then floated in a continuous stream across a bed of molten tin. The molten glass, called the float, spreads across the tin surface until it reaches an equilibrium thickness of approximately 0.28in (7 mm). The thickness may be further manipulated by a system of conveyors and guides to within a range of 0.016 to 1 in. (0.4 to 25 mm).

The slight greenish cast typical of conventional soda-lime glass is produced by the presence of iron oxide in the float chemistry, Small variations in the chemistry of the material mix can result in color variations, referred to as body tints, in the float product. Similarly, reducing the iron content of the float chemistry produces low-iron or superclear glass. Following such stringent technical conditions makes Vitra Tuff one of the best toughened glass brands in Patna.

The glass used in architectural applications begins as an annealed flat product of the float glass process, which is typically subject to modification through some form of post processing, thereby adding value. Secondary processes include various combinations of heat treating, laminating, fritting, coating, and panel fabrication.

Introducing colors to the Float glass

Tinted glass, sometimes called body-tinted glass, is achieved through the addition of small amounts of metal oxides to the float. This provides useful changes to the solar, optical transmission and reflection behavior of the glass without altering its basic physical properties. The light transmission properties, and thus the color, can be changed within limits by this subtle alteration of the glass chemistry, iron oxide, cobalt oxide, selenium and other chemicals can be used in very small quantities to modify solar transmission properties. Bronze, green, blue and gray are among the colors that can be produced this way. We treat our glass manufacturing as a work of art which makes us one the best toughened glass company in Patna.

The common performance objective in using tinted glass is to minimize infrared transmission with minimum reduction in the visible light spectrum. Green glass is most effective in this regard. There are limitations to the use of a simple body tint in pursuing this performance objective, however, Body tints are limited in their spectral selectivity, and their effectiveness in reducing solar heat gain is largely a function of the darkness of the tint. The darker tints quickly begin to reduce transmission of the visible light spectrum, a generally undesirable effect of tinted glass. Body-tinted glass can be combined with other coatings to enhance its solar performance and after its appearance.

Laminated and Insulating Glass Units

Laminated glass consists of two or more pieces, or plies, of glass bonded together at the mating surfaces. This is typically accomplished through the use of a sheet material, called an interlayer, that acts as the bonding agent. Laminated glass assemblies can utilize tinted-glass, high performance coatings, silk-screened patterns, and pigmented interlayers, alone or in combination. Glass lamination is primarily intended to improve the structural properties of glass by compensating for its brittle behavior. Laminated glass qualifies as safety glass in most situations. Our wide variety of architectural glass products makes us one the premium toughened glass manufacturers in Patna.

Insulating glass, as the name implies, is a strategy to improve the thermal performance of the glass. The product, typically referred to in the industry as an insulation glass unit (IGU), is composed of two glass lites separated by an air cavity and hermetically sealed around its perimeter. Air, compared to glass, is a relatively poor conductor and thus provides an effective insulation layer between the two glass lites. A facade or window utilizing IGUs is sometimes referred to as double-glazed. Double glazing need not stop with two lites; IGU with three glass panels (triple-glazed, with two hermetically sealed cavities) have become increasingly common in window applications, and more layers are certainly conceivable, with cost being the practical limitation.

Owing to our expertise in glass manufacturers, now architectural glass retailers can trust in Vitra Tuff, one of the best toughened glass brands in Patna, Bihar.